IMPORTANT INSTRUCTIONS

IMPORTANT INSTRUCTIONS

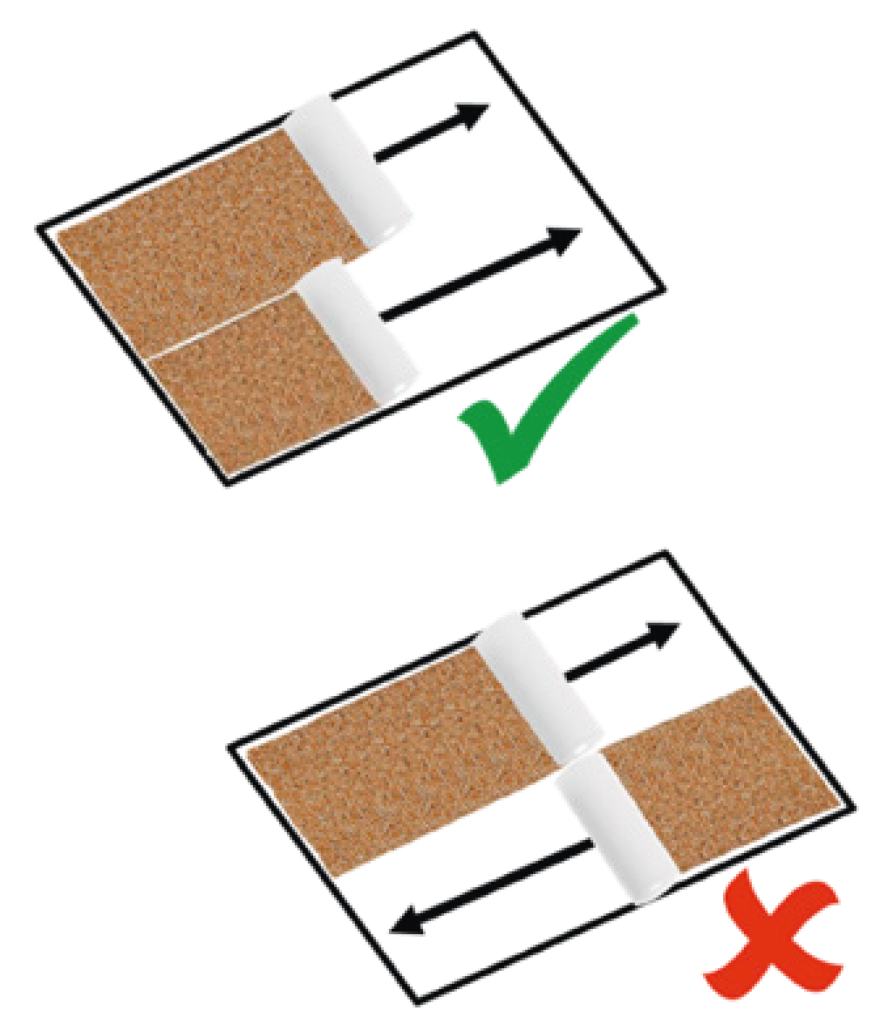

Generally, we recommend using only material coming from the same production number (see label) when installing pool liners in the floor and wall areas of a swimming pool. For larger pools, it should at least be ensured that rolls with the same charge number (see label) are used for each level. Before welding the material at the floor area, the liner rolls must be laid out in the pool ground to ensure that the membranes match in color. To avoid unwanted optical effects, the liner rolls must always be installed in the same direction. For this purpose, the bottom membranes are to observe and control from different angles from all sides of the pool.

Please inform us before welding if you noticed any significant difference in color or reflection. Slight differences in color and reflection are common, cannot be technically avoided and do not constitute a reason for complaint. Before final assembly, an installer is responsible for verifying the accuracy and functionality of the material and welding seams (see text above). After welding, please check the tightness of the welding seams.

Embossed pool liners: We recommend welding head to head. To achieve sealed tightness of the liners, welding should be performed more slowly and applying more pressing force during pressing than with conventional swimming pool liners. We recommend using a separate pool liner flange made of not embossed pool liners for fittings with a fixed loose flange connection, if necessary.

02/2025 rev. 10